What Are Your Half-filled, or Empty, Racks Costing Your Business?

What Are Your Half-filled, or Empty, Racks Costing Your Business?

Harnessing the Power of BI Business Intelligence to Optimise Warehouse Space Utilisation and Increase Revenue

Do you know how many rack locations you have, which are free to take stock, and their locations?

Does this warehouse operation scenario sound familiar? You setup, or renovated, your warehouse operation eight years ago back in 2010 when you implemented a shiny new racking system that held, say 2,500 pallet spaces of various heights to suit your then customer needs. So, let’s say that your storage capacity was: 1,000 @ 1.6m, 1,000 @ 1.8m and 500 @ 2.1m.

It’s now 2018 and you, and your operations team, still believe you have the same 2,500 pallet spaces – with the same multiple heights – as you did when you installed your racking system but…

…can you answer the following potentially revenue reducing questions?

-

How many locations do I have in total?

-

What is my current Fill Capacity – is it 50%, 80%, 95% or…?

-

What is my current racking configuration – is it standard, drive-in, mobile?

-

How many locations now hold my original 1.6m, 1.8m or even 2.1 metre pallets?

-

Which locations are currently out of use – and what is this costing me in lost revenue?

-

Did I remember to consider any more recently added building structures, coolers, or other objects now blocking access to my valuable locations?

-

Have any of my rack heights been changed, removed or added – and how has this affected my overall storage efficiency?

-

Are any of my locations over occupied, and what is the reason for this?

“We’ve never come across any warehouse operation team able to answer most, if any, of the above questions accurately”. Alan Farrell, Business Intelligence Manager, Principal Logistics Technologies.

“We’ve never come across any warehouse operation team able to answer most, if any, of the above questions accurately”. Alan Farrell, Business Intelligence Manager, Principal Logistics Technologies.

Now you see it: Warehouse Space Availability by Chamber

Now you see it: Warehouse Space Availability by Chamber

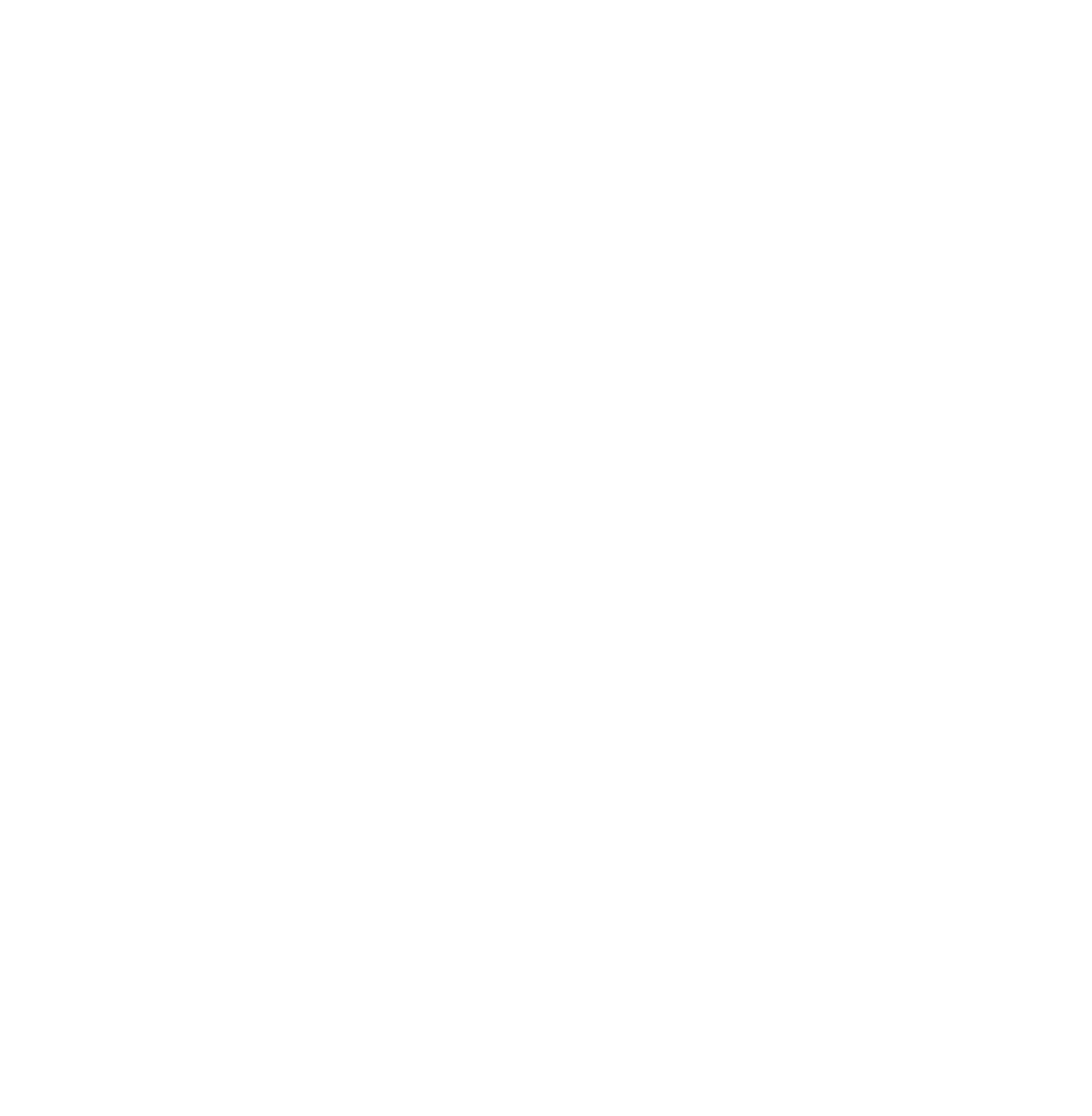

The above image is a visual representation of a warehouse, showing the space availability

by chamber, colour coded to show free space and over occupied locations (mis-scans).

The Detail: Warehouse Location Breakdown

The Detail: Warehouse Location Breakdown

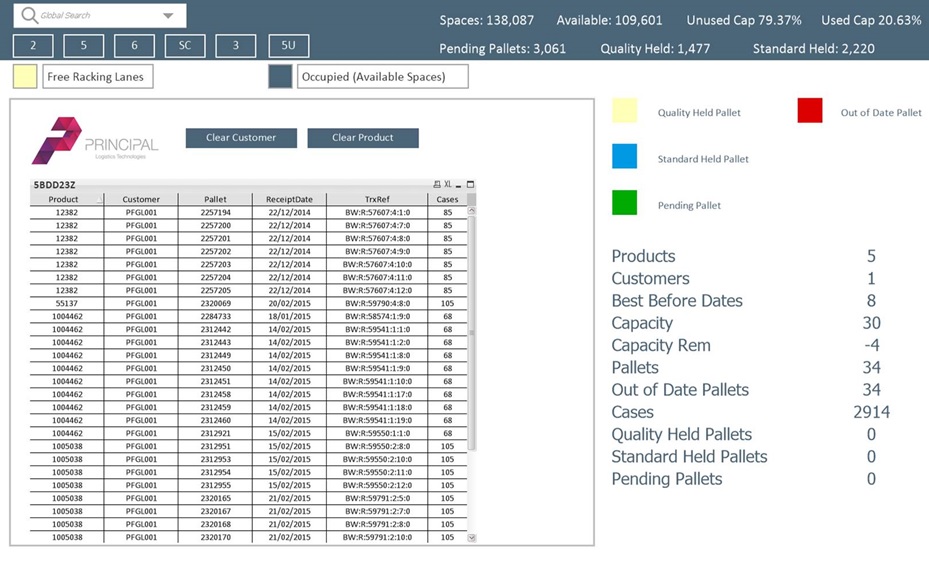

When the user selects a location within the chamber the Business Intelligence software displays the products in those locations, with a detailed breakdown of relevant stock information.

We ask the above questions early on in our engagement process as, when asked, we can find no warehouse operator with the answers – and how would they know without Business Intelligence to hand? The power of BI which, when included with our in-house developed ProWMS Warehouse Management Software, provides an always-on indication of warehouse capacity, which in turn maximises revenue keeping your ROI on target.

We just love to develop innovative solutions which optimise our client’s warehousing operations, reducing Opex and ultimately increasing ROI. If you are experiencing Warehousing or Supply Chain operation issues or bottlenecks – or just need improvements to stay ahead of the competition – then ask us how today.

Previous Article

McArdle Skeath 12,500 sq.m Dublin Warehouse OpeningNext Article

Warehouse Operation & Back Office Cost Savings ModelWe'll assume you're OK with this, but you can opt-out if you wish.Accept Reject Read More