Will Robots & AI be Running Your Warehouse Soon?

Will Robots & AI be Running Your Warehouse Soon?

Warehouse Automation, Robotics and Artificial Intelligence

Is your business ready for the Second Economy?

Joe O’Shea, Principal Logistics Technologies

I’ve seen a lot of technological changes since I started working in the mid-90’s. Email started to become popular, the web around the same time. I remember the old Motorola Brick cellular phone with the big battery, 35mm cameras and the excitement of collecting photographs after getting them processed. The wow factor the first time I saw an instamatic camera. Now all this technology, and more, is on the mobile phone in your pocket.

I’ve seen a lot of technological changes since I started working in the mid-90’s. Email started to become popular, the web around the same time. I remember the old Motorola Brick cellular phone with the big battery, 35mm cameras and the excitement of collecting photographs after getting them processed. The wow factor the first time I saw an instamatic camera. Now all this technology, and more, is on the mobile phone in your pocket.

Advances in technology occur quickly. The next big evolution is in robotics and artificial intelligence, or put another way, the part of the economy where machines and computers interact only with other machines and computers. Back in 2011 the term Second Economy was coined. This predicted “the biggest change since the industrial revolution”with the second economy as large worldwide as the First Economy and up to 100 million workers being displaced.

So what happened? Self-checkout tills at supermarkets, credit card swipe payments for fuel, autonomous cars. All McDonalds restaurants now have self-service screens for ordering, payment and receipt printing. Globally there are around 1.26 manufacturing industry robots per 1,000 employees (International Federation of Robotics). And there are even left and right-handed picking robots for more efficient bin filling. Rise of the machines indeed.

Only a couple of decades ago, the majority of robots were used in car manufacturing, typically on assembly lines doing a variety of repetitive tasks. Today, the number of robots has grown exponentially with around half installed into U.S. automaker plants. The remainder are spread across a wide range of factories, laboratories, warehouses, energy plants, hospitals, and other industries.

Only a couple of decades ago, the majority of robots were used in car manufacturing, typically on assembly lines doing a variety of repetitive tasks. Today, the number of robots has grown exponentially with around half installed into U.S. automaker plants. The remainder are spread across a wide range of factories, laboratories, warehouses, energy plants, hospitals, and other industries.

Keeping customers satisfied depends on fulfillment capabilities and forward-thinking warehouse operators realising their processes are a critical element in the supply chain. With new sales channels constantly emerging, customer expectations are changing. Social media, eCommerce/eFulfilment and multichannel customers have more price and product choice, and delivery methods than ever. Combining distribution and fulfillment operations into a one facility has become the holy grail in the supply chain network, as these allow a single location to stock a vast amount of products serving multiple channels.

Warehouse Shelf Stacking Optimised: Goods-to-Person – Delivering Items Direct to the Operator

One way to speed up warehouse picking, packing and putaway processes is to reduce the wasted number of miles walked by staff as they look for items on shelves. They call this Goods-to-Person. Online grocery retailer Ocado has developed its Smart Platform system where robots bring the shelf stacks to the workers, who pick out the right products and package them up to be sent out.

These robots travel many miles a day at speeds faster than a human can walk. No longer are the shelf and stacking systems static and inefficiently used. Then there’s Swarm Robotics technology. This allows multiple robots to communicate with each other to complete a common task, ideal for complex orders like the weekly grocery shop.

READ MORE: How Robotics are optimising warehouse operations (David Benady).

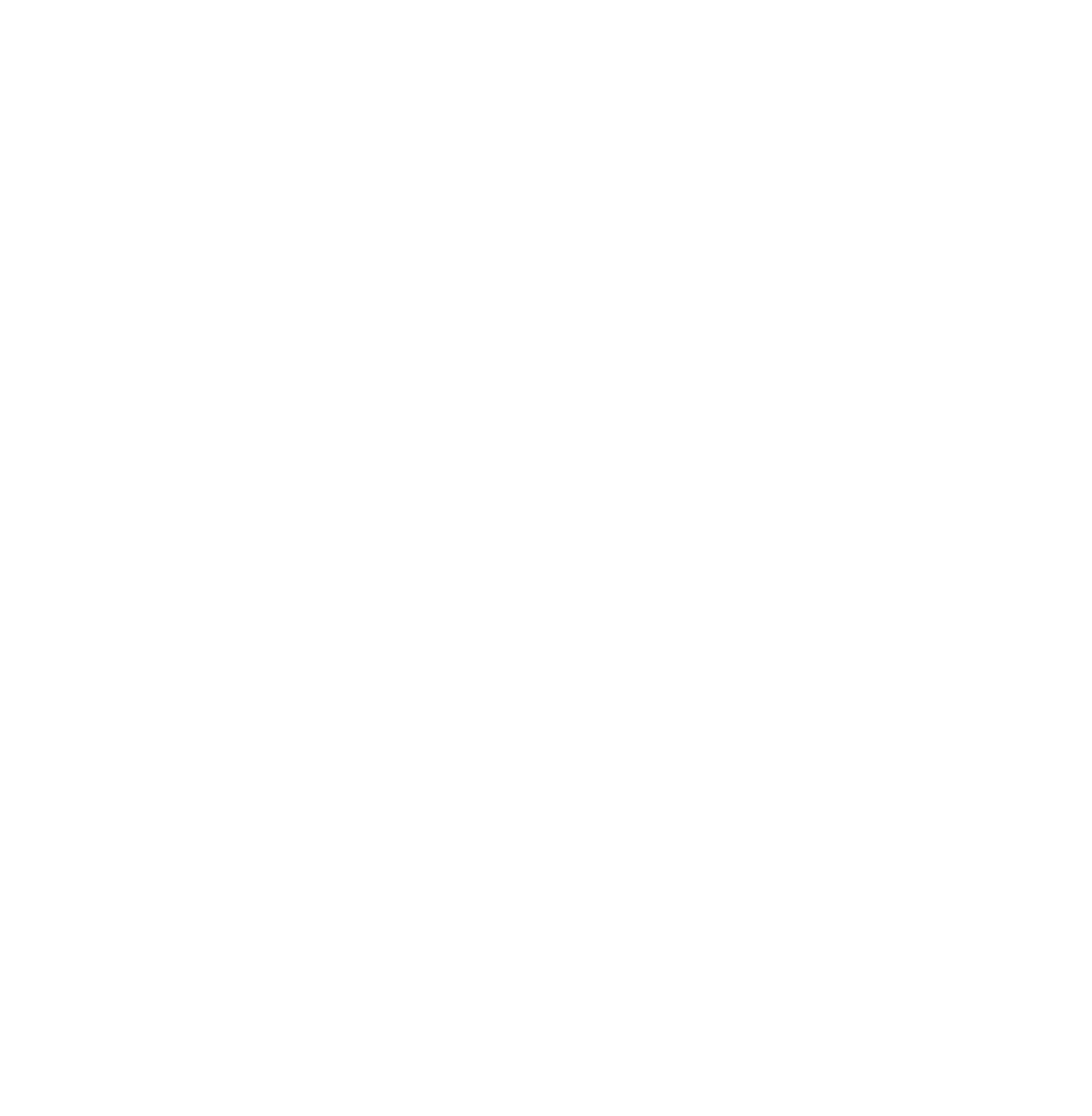

AI, Robotics and Predictive & Prescriptive Analytics: Current adoption rates across supply chain operations

“Supply chains are becoming more and more a technology-driven industry. While firms have not adopted some technologies as quickly as they thought they would back in 2014 or 2015, what we are seeing now is a big jump in these investments. Where we used to say evolve or die, what we now say is transform or die.”

Thomas Boykin, Deloitte Consulting LLP*

In late 2021, International trade association MHI, which represents the materials handling, logistics and supply chain industry, and Deloitte polled over 1,000 supply chain professionals from a wide range of global company types and industries. The findings suggest a strong takeup rate across these technologies, particularly, but not surprisingly, for robotics. What is interesting though is the very high adoption rates these business leaders forecast within 5 years.

Amazon, has deployed over 520,000 robotic drive units across its fulfilment centres since 2015 . It has robots that slide under a tower of shelves where products are stowed, lift it and move it through the fulfilment centre. They save space, enabling 50% more items to be stowed per square foot, optimising valuable storage space. This increases speed of delivery while enabling greater selection.

Amazon, has deployed over 520,000 robotic drive units across its fulfilment centres since 2015 . It has robots that slide under a tower of shelves where products are stowed, lift it and move it through the fulfilment centre. They save space, enabling 50% more items to be stowed per square foot, optimising valuable storage space. This increases speed of delivery while enabling greater selection.

DHL carried out a pilot project applying Vision Picking technology using smart glasses in a warehouse in the Netherlands as a first step in its augmented reality journey. This hands-free and paperless order picking approach is designed specifically to reduce errors. Read more about DHL and augmented reality here.

DHL carried out a pilot project applying Vision Picking technology using smart glasses in a warehouse in the Netherlands as a first step in its augmented reality journey. This hands-free and paperless order picking approach is designed specifically to reduce errors. Read more about DHL and augmented reality here.

We worked with EiraTech on a 500Kg payload robot which is perfectly designed for picking operations, like Amazon, applying the goods-to-person approach mentioned earlier whereby the product is brought on a shelf to a packing station.

One challenge we encountered concerned robots capable of lifting 1000Kgs. The concept involved full pallet movements within a standard warehouse layout. The robots operate in conjunction with existing manned reach and man-up trucks. These robots work faster, in all temperatures, without rest periods (barring brief charging periods), and they are more accurate and operate 24x7x365.

The rise of the remotely located forklift ‘Digital driver’

Global logistics provider Geodis partnered with Phantom Auto, experts in long-range remote operation software for unmanned vehicles, to develop a forklift truck that can be controlled from thousands of miles away. GEODIS remote operators, also referred to as digital drivers, can “teleport” between different vehicles and between different warehouses at the click of a button – from the safety of a remote office.

Phantom’s software provides remote operators with real-time eyes and ears around each vehicle, enabling them to safely guide the vehicles. The company is projecting a 30% reduction in the operating cost per forklift. At the same time, it is reducing health & safety risks for its forklift operators and boosting employee satisfaction by creating opportunities to work remotely.

And remember, technology innovation can sometimes go backwards, though not too often. In 2021, mobile phone manufacturer Nokia annouced that it would be bringing back a version of its bestselling 6310 model. This comes with one game and is just about smart enough to make calls, send texts and play the radio. And there’s the ‘minimal’ Light Phone with the selling point that it’ll never have social media, clickbait news, email or an internet browser.

And remember, technology innovation can sometimes go backwards, though not too often. In 2021, mobile phone manufacturer Nokia annouced that it would be bringing back a version of its bestselling 6310 model. This comes with one game and is just about smart enough to make calls, send texts and play the radio. And there’s the ‘minimal’ Light Phone with the selling point that it’ll never have social media, clickbait news, email or an internet browser.Delivering innovative solutions across 3PL, Distribution, Wholesale, Manufacturing and Retail

We’ve been delivering clever Warehouse Management Software (WMS) and Enterprise Resource Planning (ERP) solutions for over 30 years. We love to develop innovative responses that optimise our customer’s operations, add new revenue generating value-added services, reduce OpEx and deliver required ROI.

We’ve been delivering clever Warehouse Management Software (WMS) and Enterprise Resource Planning (ERP) solutions for over 30 years. We love to develop innovative responses that optimise our customer’s operations, add new revenue generating value-added services, reduce OpEx and deliver required ROI.

If you would like to discuss an initial trial, or are experiencing costly Warehousing or Supply Chain operational issues and bottlenecks – or just need improvements to stay ahead of the competition – then contact me for a chat, today.

Previous Article

Welcome Lance Ayerst, Group Operations DirectorWe'll assume you're OK with this, but you can opt-out if you wish.Accept Reject Read More