Warehouse Inventory Management UK and Ireland

Warehouse Inventory Management UK and Ireland

Warehouse Inventory Management UK and Ireland

Warehouse Stock: Location, Storage and Movement

Effective warehouse inventory management and control isn’t just about putting everything in its place so it can be located quickly. It’s about optimising warehouse operative productivity – by reducing task-time and movement as well improving stock accuracy.

The right products need to be in stock and in the right location ready for when your customers need them. And too much stock means wasted warehouse space that’s not paying for itself.

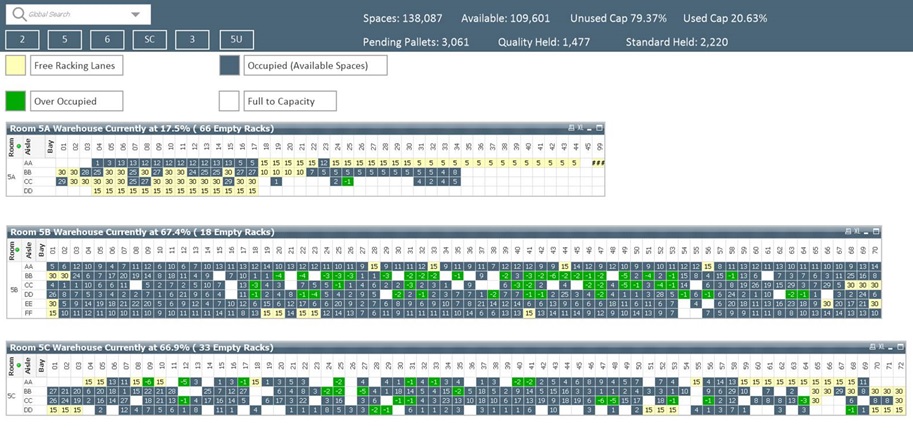

Inventory management functionality, integrated into ProWMS Warehouse Management Software, is business critical to good warehouse operation.

Real-time stock information – see our STAFFORD LYNCH CASE STUDY where we achieved a 95% stock accuracy – means that your stock levels are constantly and automatically updated. This results in optimised storage and stock movement which, in turn reduces Operational expenditure and increases profit.

Decrease warehouse operational expenditure and increase profit

Are you ready to reduce operational expenditure and boost your revenue? Contact us today to discuss our approach on: +353 (0)1 683 33 33 (Ireland) and +44 (0)121 368 0057 (UK).

As part of Supply Chain management, inventory management ensures that your warehouses always have the right finished products or raw materials, in the right quantity, in the right location and exactly when needed. And optimising your inventory by lowering overstocking, reduces wasted shelf and rack space, generating increased revenue.

Perishable products like foodstuffs, pharmaceuticals or chemicals with best before or use by dates, or that require standards adherence, need to be moved in good time to avoid spoilage and to prevent overspend and wasted space.

Warehouse inventory management software technology must-haves:

- Real-time inventory tracking

- Prevent stock shortages and overstocking (product and raw materials)

- Optimise operator movement and task time

- Demand forecasting and live reporting with what-if scenarios

- Harness proven voice and mobile enabled device technology

- Enable forward customer connectivity for stock management and control

- Ultimately reduce OpEx, improve cashflow and increase revenue

Warehouse inventory management and control management acronyms explained

Business Models:

Just-in-time Inventory (JIT), Vendor Managed Inventory (VMI) and Customer Managed Inventory (CMI) are some of the models used in stock management and control.

JIT aims to replenish inventory for organisations when the inventory is required. It attempts to avoid excess inventory and its associated costs. Companies receive inventory only when the need for more stock is approaching and is forecasted.

VMI (vendor managed inventory) and (co-managed inventory) are two business models that adhere to the above JIT inventory methods. VMI gives the vendor in a vendor/customer relationship the ability to monitor, plan and control inventory for their customers. Customers relinquish the order making responsibilities in exchange for timely inventory replenishment that increases organisational efficiency.

CMI allows the customer to order and control inventory from their vendors/suppliers. Both VMI and CMI benefit the vendor the customer. Vendors see a sales boost due to increased inventory turns and cost savings realised by their customers, and customers realise similar benefits.

Costing techniques:

The management of stock in the supply chain involves managing physical quantities as well as costs of goods as these travel through the supply chain. Some of the following techniques are applied to control the finance element of inventory management.

Retail method:

- Weighted Average Price

- FIFO and LIFO (First In First Out &Last In First Out)

- LPP (Last Purchase Price)

- BNM (Bottle Neck method)

We love to find clever solutions that improve on our client’s operations and ROI. If you’re experiencing Warehousing or Supply Chain operation issues or bottlenecks – or just need improvements to stay ahead of the competition – then Ask us How, Today.

We love to find clever solutions that improve on our client’s operations and ROI. If you’re experiencing Warehousing or Supply Chain operation issues or bottlenecks – or just need improvements to stay ahead of the competition – then Ask us How, Today.

Previous Article

Social Distancing: Protecting Your 3PL Warehouse & WorkforceNext Article

8 Best Practice Tips for Warehouse OptimisationWe'll assume you're OK with this, but you can opt-out if you wish.Accept Reject Read More